Jenny's Sock Shop

Jenny's Sock Shop is only open by appointment. Please make sure to call or email if you want to visit.

- Phone: (715) 892-1630

- Email: info@blackscliff.com

If you can't make it to the shop, Jenny will text pictures of items so you can shop from your phone, then she will ship the items out.

Keeping Toes Toasty

Antique knitting machine has made this reader a darn good sock maker.

By Linda Wrobel, Arbor Vitae, Wisconsin

Parents commonly sock away money into college funds for their children. Jenny Gibson does that literally.

In the past 5 years, she’s knitted more than 3,000 pairs of colorful woolen socks, putting one son through school, financing a second one midway through his studies, and sending a third one to begin classes this fall.

No wonder Jenny’s known as The Sock Lady!

Jenny and her husband, Troy, own and operate Black’s Cliff Resort in Hazelhurst, an up-north getaway that has drawn families for generations. You’d think their busy lives as year-round hosts to guests in 11 lakeside cabins would consume all their time.

Not entirely. A serendipitous discovery of a relatively obscure knitting machine changed Jenny’s life in 2013. It happened when she read a blog post about making socks on an antique machine. After studying a photo with the story, Jenny was intrigued and asked questions.

Dry Socks Saved Lives

It turns out that hand-cranked sock machines have been around since the mid 1800s. During World War I, dry socks were critically important to ward off the scourge of trench foot. In those days before antibiotics, it could kill a soldier.

The Red Cross gave away hundreds of thousands of circular sock machines to volunteer families in the U.S. and Canada, along with 10 pounds of wool…enough for 30 pairs of socks. If they knitted that many socks, the machine was theirs to own and supplement the family income.

During World War II, a similar effort continued. But as the conflict carried on, the metal in these machines was so valuable they were melted down for munitions.

Jenny’s curiosity led her to price the machines on eBay. The one she found was $1,400 which made her hesitate. Not only was Jenny and Troy’s oldest son headed to college, they were building a new office and gift shop at the resort.

To buy this machine, they’d have to gamble their tax return. After researching YouTube videos to ensure she could teach herself how to use the machine, Jenny swallowed hard and clicked, “Buy It”.

Hose Were the Days

A week later, her 1924 machine arrived, built by Gearhart Knitting Machine Company of Missouri. The seller sent information including the original price tag of $5. After watching more online videos, Jenny and Troy assembled the machine. Now she had to learn to use it.

For a month, Jenny visited a local coffee shop with high-speed internet. There she could download and watch instructional videos over and over.

Following those instructions, Jenny finally finished a sock. “It took about 2 days of prayer,” she laughs. “I almost threw that dang machine in the lake!”

Slowly, the socks started coming off the machine. Soon everyone in Jenny’s family had a pair and then she started making them to sell.

When the resort’s new office and gift shop was completed, Jenny began filling it with colorful socks. Within 3 months of selling her first pair, she’d paid for the machine. The Sock Lady was on her way!

Since then, four circular sock machines have found a home here. The Gibsons’ latest acquisition is a 1902 Gearhart nicknamed “the Knee Knocker”. This machine operates with hanging weights that can sway and hit the operator’s knees. Jenny and Troy are getting this old machine going again.

These days, Jenny can make a pair of socks in an hour. In fall, you can see her at craft fairs around Oneida and Vilas Counties, where folks watch her crank out colorful socks and find the perfect pair for cold Wisconsin winters.

One of Jenny’s machines has even been customized to ease her work. Hand cranking through 3,000 pairs of socks brought tendinitis to her arm. But a sock maker in Missouri devised a way to rig bicycle pedals to a machine.

Jenny’s now using that method. You might say she’s a “sock peddler” in more ways than one!

-----

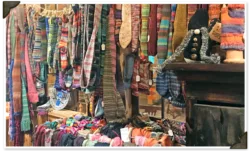

Socks, fingerless gloves, scarves and headbands are made from various yarns

- No Wool Acrylic

This is for those who don't want wool - 50% Superwash Merino Wool, 25% Bamboo and 25% Nylon

This is great for folks that want warm wool socks but are afraid they are itchy. Bamboo softens the wool making them soft and warm - 75% Superwash Wool and 25% Nylon

Superwash Wool means you can wash them in the washer, just don't roast them in the drier. These socks are thicker and warmer